1. Marcabamba Peru

A 105 kW system supplying 4 mountain villages.

This is a perfect example of modern technology being introduced into a third world situation. In the High Andes of South America, electricity is still pretty much a luxury most people do without. The United Nations put up the money for a number of hydro plants in Peru, such as this system, built by Dependable Turbines of Vancouver BC. This photo was taken while commissioning the plant in the summer of 2000. The project employed locals to build the 2 km long aqueduct emptying into the settling basin pictured below. The water drops 650 feet through 12 inch steel penstock to the power house below and produces 105 kW of electricity.

(TOC)

2. Christian Valley

A 125 kW system supplying a small camp.

Even very old equipment finds a practical use. This 80 year old generator was salvaged from a small mining town and put to use powering the small village of Christian Valley in the BC interior.

With an output of 85 kW, there is ample power to provide light and heat to the isolated community. Note the large size of the open frame generator, and the separate exciter generator. Modern day equipment is a fraction the size, and capable of much greater output.

(TOC)

3. Hoodicroft

A fantastic example of what one man can build.

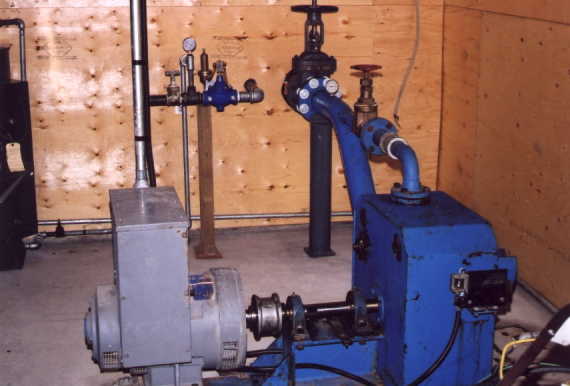

I first met the owner of this project on a trip to visit Frank Poirier, the well known Malibu caretaker, now living in the Kootneys. This hydro project was built 10 years ago by one man. The concrete dam, pipeline, and power house was built over a few years as funds permitted. The turbine was completely home built, the steel welded and the machining done at home.

The generator consists of a rewound electric motor operating as a generator. This is a common technique, and results in an efficient machine at a fraction of the cost of a synchronous generator. It does require a talent few posses.

After the success of his first project, he is now working on a much larger 280 kW plant. This will involve a concrete dam, a large penstock and concrete power house. Again, most of the components are entirely home made or modified from existing equipment. This guy is the most talented self taught engineer I have yet met in my 20 or so years in this field.

The 10 kW power house. |  The power house under construction. Note the home made concrete pouring bucket suspended on a cable. |

A well designed weir for the 280 kW plant. |

(TOC)

4. Beyond Base Camp

A Battery charging DC micro Hydro system.

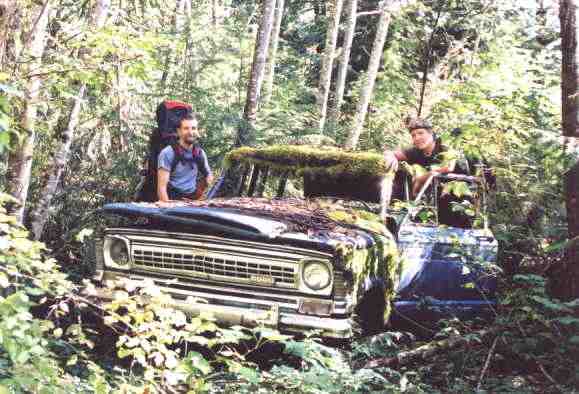

The Beyond Malibu program offers second year campers a chance to continue on with the 'Malibu Experience' in a wilderness setting. From a well equipped base camp, week long expeditions are conducted in the mountains surrounding Princess Louisa Inlet.

The base camp was 'electrified' several years ago with the incorporation of a small generating system . The main purpose of this was to do away with the potentially dangerous gas fired lanterns which had been in use for many years. Electric lights now run continually in the kitchen, equipment area, and a few out buildings.

The system generates 12 volt DC power, and uses batteries for storage. A small inverter converts the 12 volts DC to 120 volt AC for powering the laptop computer charger, small AC tools and compact florescent lights. Other lights run directly off the 12 volts batteries.

| An example of the latest in micro hydro generators, this permanent magnet unit produces 3 phase power at either 12, 24 or 48 volts, which is then rectified to DC. Water is supplied by 700 feet of 3 inch plastic pipe. Power is carried to "The Barn", the main building at base camp on 300 feet of used aluminum wire where it is fed into a battery bank. A 1500 watt inverter then produces standard 117 volt AC for use by regular appliances. |

|

The most recent additions to the power system includes automatic regulation, a 1500 watt inverter for powering a deep freeze, AC lighting, and a small hot water tank. On the left is the control room where the power is distributed, and on the right is the power house which feeds the juice to the barn through a 300 foot long cable. |

|

(TOC)

Switch gear and controls.

Switch gear and controls.

Two nozzle Pelton turbine.

Two nozzle Pelton turbine.